3D PRINTING FILAMENT

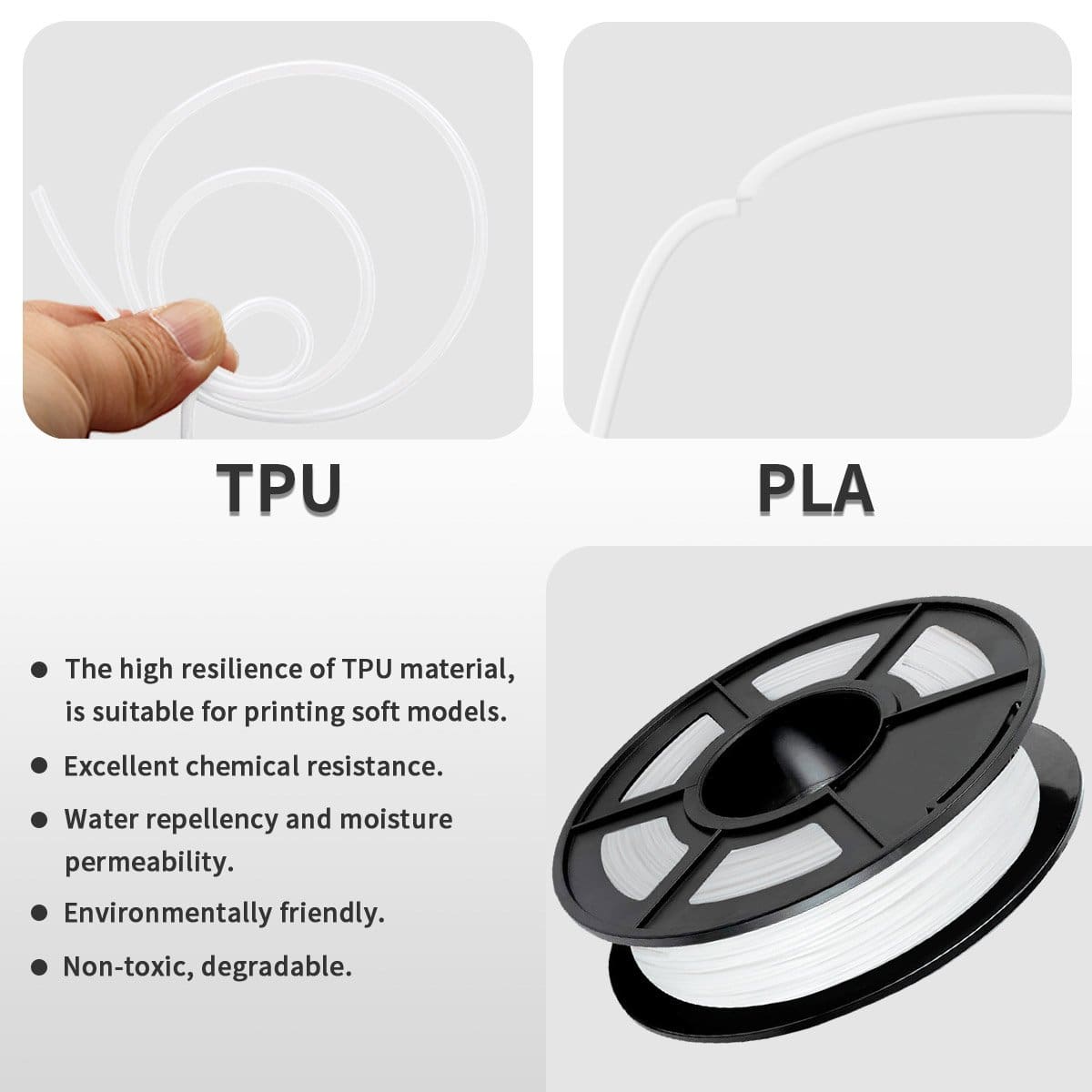

TPU

- TPU Filament 1.75mm 1KG

- Flexible, durable and abrasion-resistant

- High resilience – ideal for printing soft models

- Non-toxic & environmentally friendly

- Low Shrinkage / minimal warping

- Recommended print temperature 205-230°C

TPU (Thermoplastic polyurethane) is a flexible, abrasion-resistant thermoplastic. It’s being used in a number of manufacturing processes for both consumer and industrial use. In certain blends it can become very soft, but TPU material offers many benefits and features. 3D printed parts with TPU are durable and have the ability to withstand ambient temperatures of up to 80 degrees Celsius.

TPU is referred to as the bridge between rubbers and plastics. The material appears rubber-like, which means it can be extremely flexible, durable and smooth to the touch. All these properties and compound versatility make TPU widely used in many industries for coatings, components and customer goods. It is often used for 3D printing.

- Designed to fit with all types of FDM 3D printers.

- Environmentally friendly and non-toxic.

- Bright color, high resilience, soft and good extensibility.

- Good aging resistance.

- TPU shore hardness 95A.

Best printing practices

When 3D printing, always work in a well ventilated workspace.

In 3D printing technology, usually Acrylonitrile Butadiene Styrene (ABS) and Polylactic acid (PLA) are considered as standard plastics for printer filament but due to insufficient flexibility, they can’t be used in bending prototypes. On the other hand, TPU printing filament is flexible in nature. It can bend easily without any effect on the design, strength and durability. A mild soap can be used for its cleaning.

TPU filament has a number of features, making it a great choice for a wide range of uses. It is resistant to abrasion, oil, chemical and wearing, which makes it perfect for use in industries such as the automotive industry. printed parts of TPU are also resistant to low temperatures, which means that it does not become brittle and difficult to work with.

Be the first to review “TPU” Cancel reply

Related products

3D Printer Filament

Reviews

There are no reviews yet.