Insight

3D Printing for Rapid Prototyping: Complete Guide

Introduction

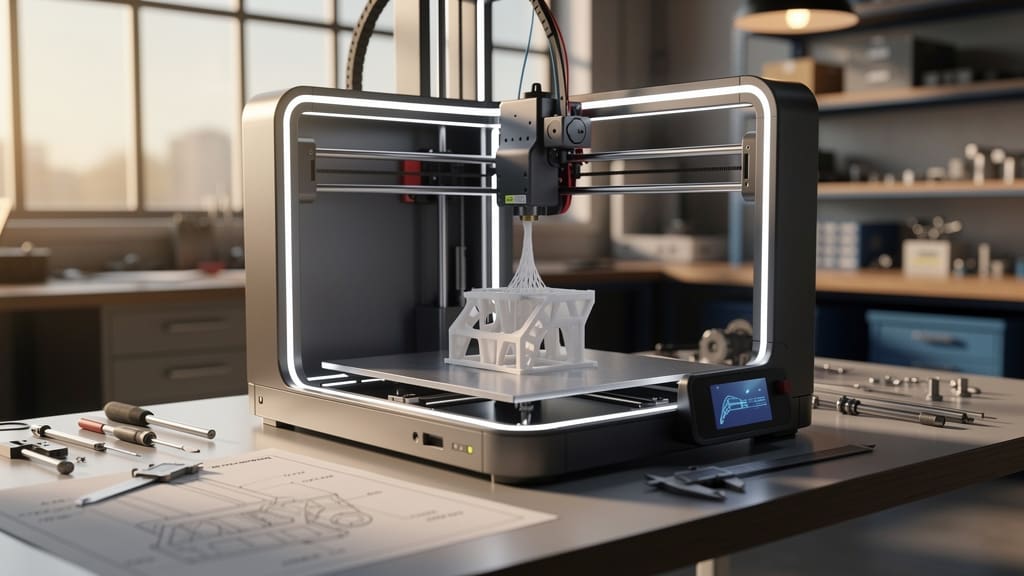

The first time we used 3D printing for rapid prototyping on a real project, it felt almost unfair. The team wrapped up a CAD model in the afternoon, sent it to the printer, went home, and came back the next morning to a ready-to-test part on the desk. No purchase orders, no machine shop queue, no anxious follow-up emails.

That experience sums up rapid prototyping: a fast, repeatable cycle where digital designs become physical parts, are tested, revised in CAD, and printed again until the design works as intended. 3D printing sits at the center of this loop because it can turn a CAD file into a solid part in hours instead of weeks.

Not long ago, prototypes meant foam blocks, clay models, and expensive machined parts that took weeks to arrive. Only big companies could afford multiple cycles. Now, desktop and industrial 3D printers sit in small shops, school labs, makerspaces, and home offices. Engineers, designers, teachers, and hobbyists all run miniature prototyping labs for less than the cost of a single machined sample.

This guide walks through how 3D printing for rapid prototyping works in practice: the workflow, printing technologies, material choices, leading applications, and where this field is heading. Along the way, we show how Sundi3D supports that process with factory-direct materials, fast delivery, and round-the-clock technical help, so every prototype—from first sketch to pre-production part—uses the right filament.

Key Takeaways

-

3D printing for rapid prototyping turns lead times of weeks into hours or days. That extra room for iteration improves designs, cuts surprises, and helps products reach the market faster and with more confidence.

-

When teams bring 3D printing in-house, the design–print–test–refine loop often fits inside a 24‑hour window: model during the day, print overnight, test in the morning.

-

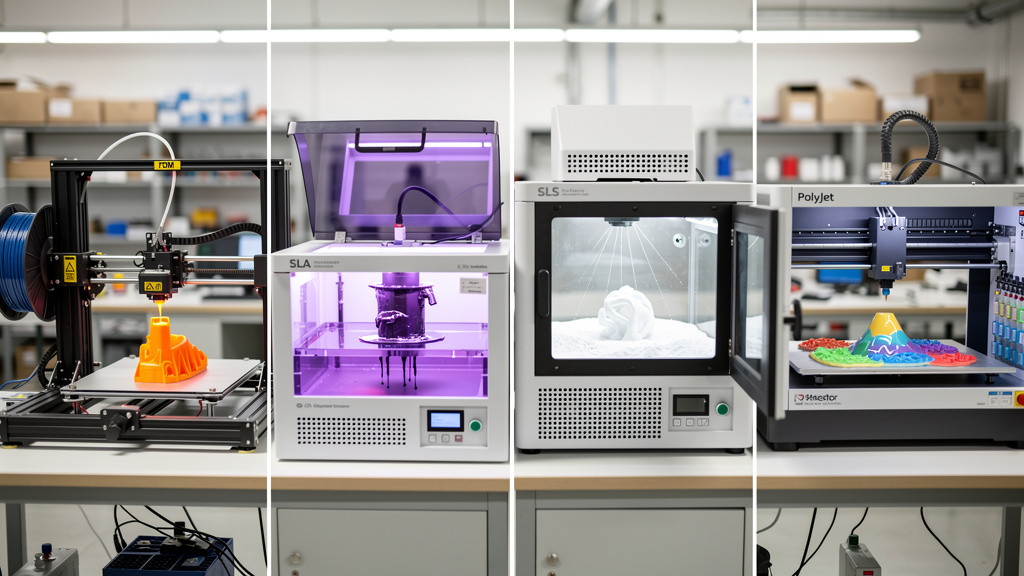

Different technologies serve different goals: FDM for strong functional parts, SLA for smooth visual models, SLS for complex durable parts, and PolyJet for ultra-realistic multi-material samples.

-

Material choice matters as much as the printer. Low-cost PLA suits early concept work, while engineering thermoplastics and composites handle serious functional testing. With Sundi3D’s standard and custom filaments plus life-long support, teams can cover every stage with the right material.

“The only way to win is to learn faster than anyone else.”

— Eric Ries, The Lean Startup

What Is Rapid Prototyping And Why Does It Matter?

By rapid prototyping, we mean using digital tools—especially 3D printing—to turn CAD data into physical parts very quickly, a process that modern 3D rapid prototyping services have made accessible to businesses of all sizes. Instead of sending drawings to a vendor and waiting, we move straight from a 3D model to a printed part on our own printer.

The process is highly iterative:

-

Design the part in CAD.

-

Print a prototype.

-

Test and review.

-

Update the CAD model.

-

Print again.

This loop repeats until the part meets performance, fit, and appearance needs. Rapid prototyping covers this entire loop, not just the print itself.

From a business perspective, this matters because:

-

Faster cycles mean faster time-to-market.

-

Early validation catches issues before tooling and large orders.

-

More iterations within the same budget lead to better products and fewer field failures.

Thanks to 3D printing for rapid prototyping, this approach is no longer reserved for global corporations. Small manufacturers, schools, research labs, makers, and freelancers now rely on it to compete at a higher level.

The Evolution: From Traditional Methods To 3D Printing

Before 3D printing for rapid prototyping, teams depended on manual and subtractive methods. Early models were carved from foam or clay to study size and style. These helped with looks and feel, but they were fragile and could not represent real mechanical behavior.

For functional checks, companies ordered machined parts or other conventionally made pieces. Each iteration could cost hundreds or thousands of dollars and take weeks. That meant most projects allowed only a few full prototypes, and many designs reached tooling after limited testing.

The first commercial 3D printers in the late eighties and nineties changed that picture. At first, 3D printing mainly produced visual and basic functional models, so people almost used “rapid prototyping” as a synonym. Over the last decade, materials and machines have improved enough to handle strong thermoplastics, composites, and high-performance resins suitable for production parts, with metal 3D printing expanding capabilities even further for industrial applications.

Today, the term additive manufacturing is often used for production-grade work—jigs, fixtures, and end-use parts—while rapid prototyping remains one of the most valuable early applications. Sundi3D has followed this shift for a decade, building filament lines and custom materials that keep pace with what modern printers can do.

How 3D Printing Accelerates The Prototyping Workflow

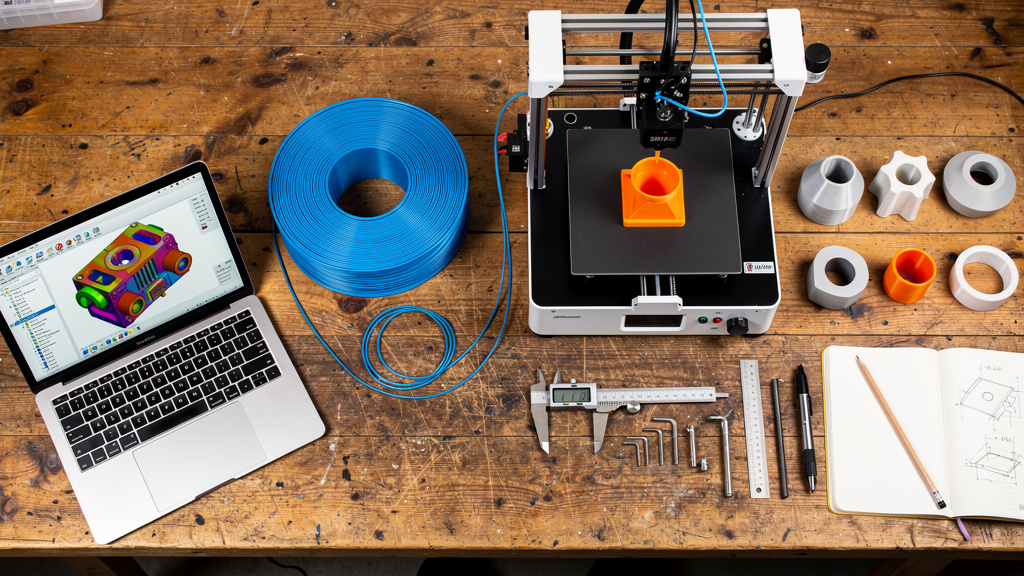

The strength of 3D printing for rapid prototyping comes from a direct, repeatable workflow:

-

Model the part in CAD.

-

Export to STL or a similar neutral file.

-

Import into slicer software.

-

Choose material and print settings.

-

Generate the toolpath and print.

-

Perform basic post-processing.

-

Test, learn, and revise.

Because this loop is fast, a full design–print–test cycle often fits inside a single day. A housing can be adjusted in the morning, printed during the afternoon or overnight, and checked in an assembly the next morning.

This workflow also removes classic bottlenecks:

-

No waiting for vendor quotes or purchase orders.

-

No queue at a busy machine shop.

-

Modern printers and slicers are accessible enough that any trained team member can run them.

At that point, the main limits become design time and material availability. Sundi3D helps reduce the second constraint with a wide range of filaments and 24‑hour shipping from our factory, so material stock rarely slows projects.

Five Game-Changing Benefits Of 3D Printing For Prototyping

3D printing for rapid prototyping delivers clear, measurable gains across projects of all sizes.

Dramatically Reduced Lead Times

Traditional machining could take weeks or months between CAD and a prototype, especially for complex shapes. Each round meant quotes, approvals, setup, and shipping. With 3D printing, that path shrinks to hours or a few days. Many teams report moving from a full week to half a day for similar parts, allowing far more design cycles in the same schedule.

Significant Cost Reduction

Old-style prototypes needed expensive setups, cutting tools, and skilled labor, pushing per-part costs into the hundreds or thousands of dollars. In contrast, 3D printing for rapid prototyping uses affordable materials, minimal setup time, and automated machines.

That shift:

-

Cuts cost per part from hundreds of dollars to tens of dollars.

-

Frees budget for more experiments.

-

Encourages teams to test multiple design directions.

Sundi3D’s factory-direct pricing on PLA, ASA, and other filaments trims costs further while maintaining consistent quality.

Greater Design Freedom And Innovation

Because 3D printers build parts layer by layer, many traditional limitations disappear. With 3D printing for rapid prototyping, designers can explore:

-

Bold curves and organic shapes.

-

Lattice interiors for weight reduction.

-

Complex internal channels and assemblies.

Early on, there is less pressure to follow strict design-for-manufacture rules, which encourages creative thinking. Teams often print several variations of a handle, bracket, or enclosure at once, compare them side by side, and proceed with the best option.

“Fail early to succeed sooner.”

— David Kelley, Founder of IDEO

User-Friendly Accessibility

Modern printers and slicers are built for regular users, not only expert technicians. Once a team learns the basics, anyone can go from CAD file to printed part. This accessibility is a big reason 3D printing for rapid prototyping works so well in schools, small businesses, and makerspaces.

When questions appear, Sundi3D backs customers with 24/7 technical support, so even new users can resolve issues and keep parts flowing.

Smooth Prototype-To-Production Transition

Another major advantage is that the same platforms often support both early tests and near-production parts. A team may begin with low-cost PLA to study form and fit, then move to stronger materials such as ASA or nylon for demanding functional trials—often on the same FDM printer.

Because geometry stays consistent, there is no need to redraw parts for different processes. Sundi3D’s filament line spans from everyday PLA to industrial ASA and custom blends, helping teams move from sketch models to serious pre-production parts within a familiar workflow.

The Three Stages Of Rapid Prototyping With 3D Printing

Planning 3D printing for rapid prototyping by stages keeps costs controlled while building confidence in the design.

Stage 1: Concept Exploration And Visual Prototypes

In this first stage, ideas leave the screen and turn into objects we can hold. The focus is on:

-

Form and size

-

Basic ergonomics

-

Visual appearance

Materials like PLA shine here: low-cost, easy to print, and good surface finish.

Typical uses include:

-

Several handle or grip shapes for ergonomic trials

-

Different enclosure layouts for button and screen placement

-

Early “looks-like” models for stakeholder reviews

Sundi3D PLA filaments are non-toxic, consistent in diameter, and reliable across long print runs—important when printing many variants for a single review session.

Stage 2: Functional Prototyping And Performance Testing

Once the basic form is set, the next question is whether the design works under real loads. In this stage, we print “works-like” parts that mimic final components.

Teams usually switch to engineering-grade materials such as:

-

ABS or ASA for impact resistance and higher temperature performance

-

Nylon for strength, wear resistance, and some flex

-

PETG for a balance of printability, strength, and chemical resistance

These prototypes support:

-

Stress and fatigue testing

-

Snap-fit and assembly checks

-

Environmental testing (heat, cold, UV, moisture)

Sundi3D’s industrial ASA is often chosen for outdoor or automotive parts that must resist sunlight and weather during extended use.

Stage 3: Product Validation And Pre-Production

In the final stage, prototypes must closely match the finished product in size, function, and often appearance. 3D printing for rapid prototyping here supports:

-

Final tolerance checks

-

Certification tests

-

Pilot runs and design sign-off

Teams may use:

-

Printed rapid tooling for short-run molding

-

Custom jigs and fixtures for reliable measurement

-

Filaments matched to target production plastics

Sundi3D’s customization service helps align filament properties with planned production materials. A medical device team, for example, might print both housings and test fixtures from custom-formulated filament before submitting data to regulators.

Selecting The Right 3D Printing Technology For Your Prototypes

Not every printer fits every job. To get the most from 3D printing for rapid prototyping, we match technology to needs for accuracy, surface finish, strength, and cost.

Fused Deposition Modeling (FDM)

FDM feeds thermoplastic filament through a heated nozzle, building parts layer by layer. It is:

-

Affordable

-

Easy to operate

-

Compatible with many materials (PLA, ABS, PETG, nylon, TPU, ASA, and more)

FDM is ideal for:

-

Brackets, housings, and clips

-

Jigs and fixtures

-

Everyday mechanical testing and low-volume production

Sundi3D focuses strongly on this area, offering a broad range of FDM filaments tuned for reliable printing.

Stereolithography (SLA)

SLA uses a laser to cure liquid resin in thin layers, creating parts with excellent surface quality and fine detail. It is the go-to method when we care about:

-

Smooth surfaces

-

Small text and sharp features

-

High-detail visual models

Common uses:

-

Client presentation pieces

-

Dental models

-

Patterns for casting or molding

The trade-off: many SLA resins are more brittle than FDM thermoplastics, so they are less suited to high-stress mechanical testing.

Selective Laser Sintering (SLS)

SLS spreads thin layers of powder (usually nylon) and uses a laser to fuse selected regions. Unfused powder supports overhangs from all directions, so no additional support structures are needed.

Key benefits:

-

Strong, durable nylon parts

-

Complex geometries and internal channels

-

Functional testing and low-volume production

Surface finish is slightly rougher than SLA, but this is acceptable in many engineering contexts.

PolyJet And Multi-Material Printing

PolyJet printers jet tiny droplets of liquid photopolymer and cure them immediately with UV light. They can mix materials and colors within a single part, making it possible to print:

-

Combined soft and hard regions

-

Clear windows and labels

-

Full-color, realistic models

PolyJet is widely used for:

-

Show-and-tell prototypes

-

Overmolded parts

-

Detailed medical and consumer product models

Because color and texture come straight from the printer, little finishing is needed for appearance models.

Programmable Photopolymerization (P3)

P3 is a newer resin method that combines high accuracy with materials designed to behave like engineering plastics. It is well suited to:

-

Tight-tolerance parts

-

Functional components with real load requirements

-

Small production runs on the same platform used for prototypes

In many workflows, P3 bridges the gap between rapid prototyping and low-volume manufacturing.

Choosing The Right Materials For Each Prototyping Stage

Picking the right material is just as important as picking the printer. When planning 3D printing for rapid prototyping, we match materials to the questions we’re asking at each stage.

Cost-Effective Materials For Concept Models

For early form and fit work, PLA is the default choice:

-

Prints easily on almost any FDM machine

-

Gives a smooth surface for visual reviews

-

Works well for simple assembly checks and classroom projects

Its low cost means we can print many versions without stressing the budget. Sundi3D PLA filaments are odorless, non-toxic, and tightly controlled in diameter, helping avoid jams and inconsistent extrusion.

Engineering Materials For Functional Prototypes

When we need more realistic mechanical behavior, we move to engineering materials:

-

ABS – impact resistance and moderate heat tolerance

-

ASA – similar to ABS but with excellent UV and weather resistance

-

Nylon – high strength, wear resistance, and some flex

-

PETG – easy printing with solid strength and chemical resistance

Sundi3D’s industrial ASA range is popular for outdoor and automotive parts that must survive long-term exposure.

Specialized Materials For Specific Requirements

Some projects need special traits:

-

TPU / TPE for flexible grips, seals, and wearable items

-

Fiber-filled composites (carbon or glass) for stiffer, lighter parts

-

High-temperature plastics such as polycarbonate for hot environments

-

Dissolvable supports for cleaning complex internal channels

Through Sundi3D’s customization service, teams can align filament properties with demanding use cases so their rapid prototyping results mirror real-world behavior more closely.

Material Selection Best Practices

A simple approach:

-

Start with PLA or similar low-cost material for concept work.

-

Move to PETG, ABS, or ASA once strength and durability questions appear.

-

Use the same or very similar materials to production for late-stage tests.

When in doubt, talking with material experts helps. Sundi3D’s technical team spends much of its time advising customers on filament choices, often saving several failed test runs.

Real-World Applications: Industries Changed By Rapid Prototyping

3D printing for rapid prototyping appears in nearly every field that designs physical products, but each sector uses it in slightly different ways, from structural electronics to medical devices.

-

Consumer products: Fast trials of shapes, button layouts, textures, and colors. Designers can hold several versions of a phone case or kitchen tool in a day and gather user feedback before tooling.

-

Automotive and aerospace: Interior trim, ducting, brackets, clips, and structural parts printed for vibration, heat, and assembly testing. SLS and high-end FDM machines are especially common here.

-

Healthcare: Printed anatomy models for surgical planning and device prototypes for ergonomic and functional testing, with 3D printing offering a novel approach for customized pharmaceutical and medical applications. High accuracy is vital, so SLA, PolyJet, and P3 are widely used.

-

Education and research: Labs filled with desktop printers so students can design, print, and test ideas firsthand instead of just reading about them.

-

Industrial equipment: Custom hardware, tooling, and replacement parts printed to shorten lead times and cut inventory.

-

Creative and educational tools: Artists and teachers use Sundi3D’s SUNDIPEN 3D pens with low-temperature PCL filament to sketch structures in space and build quick models or teaching aids directly on the desk.

Across all of these, the common thread is the ability to try ideas quickly, discard weak ones cheaply, and keep improving the promising ones.

Success Stories: Measurable Impact Of Rapid Prototyping

Many organizations have measured the impact of 3D printing for rapid prototyping, and the numbers are striking.

-

Centor, an industrial door manufacturer, compared machined prototypes (about $800 each and a week of lead time) to in-house prints (about $10 each and roughly 12 hours). Cost dropped by around 98%, and lead time shrank dramatically.

-

Caldwell Manufacturing, a global hardware maker, cut prototype costs from $500–$3,000 per part down to about $30 when printed in-house. Lead times went from as long as eight weeks to just three days.

-

Santa Cruz Bicycles used high-performance thermoplastics and 3D printing to refine a new frame, going from digital design to a rideable test frame in only a few weeks, trimming roughly four pounds from the final design.

-

Microsoft engineers use PolyJet printing for laptop and tablet models with working hinges and realistic textures, supporting detailed design reviews of the Surface line.

-

Ford relies on SLA and SLS printers for both cosmetic and functional parts, while SEONG YUN TECH improved accuracy and speed by switching from older methods to a modern resin printer.

Behind these success stories sit reliable machines and, just as importantly, consistent materials and strong support. Sundi3D contributes on that front with stable filament quality, factory-direct supply, and 24/7 technical help.

Best Practices For Implementing Rapid Prototyping In Your Workflow

Putting 3D printing for rapid prototyping into real projects involves more than buying a printer. The biggest gains come when goals, tools, people, and processes align.

Good practices include:

-

Define the goal of each prototype.

Is it for appearance, ergonomics, strength, manufacturability, or user feedback? Clear goals guide material and printer choices. -

Start simple with equipment and materials.

For many teams, one or two FDM printers plus PLA and an engineering filament (such as PETG or ASA) cover most needs. Add SLA or SLS later as requirements grow. -

Treat prototyping as a steady loop.

Plan regular print slots, write simple test procedures, and record results. Even a shared spreadsheet listing each prototype and outcome prevents repeated mistakes. -

Secure a reliable material pipeline.

A trusted supplier with fast shipping and consistent quality avoids stock-outs. Sundi3D’s factory-direct logistics and 24‑hour shipping window from China keep printers running. -

Decide what to print in-house vs. outsource.

Daily work often belongs in-house, while very complex SLS or PolyJet parts can go to service bureaus. Many teams mix both. -

Use expert support.

Suppliers with real technical depth—like Sundi3D’s 24/7 support team—can help with material selection, troubleshooting, and tuning.

Tracking metrics such as average prototype cost, lead time, and number of iterations makes it easier to show management how rapid prototyping is paying off.

Common Challenges In Rapid Prototyping And How To Overcome Them

Even with clear benefits, teams often face similar hurdles when adopting 3D printing for rapid prototyping.

1. Picking the right material

With so many options, it is easy to use expensive engineering plastics for simple concept models or weak materials for demanding tests. A practical rule:

-

Use PLA for early concepts.

-

Move to PETG, ABS, or ASA as strength needs increase.

-

Switch to production-like materials for final tests.

Sundi3D helps by recommending starting points and, when needed, developing custom filament blends.

2. Print failures and quality issues

Warping, weak layer bonding, or clogged nozzles usually trace back to poor filament, incorrect settings, or lack of maintenance. Using filaments with tight tolerances (like Sundi3D’s), following material-specific print guidelines, and keeping machines calibrated solves many issues. When problems persist, real-time support makes a big difference.

3. Slow iteration despite owning printers

Sometimes internal approval steps, scheduling conflicts, or empty material shelves cause delays, not the printers themselves. Shorter sign-off chains, planned print windows, and a small buffer of essential materials keep the loop fast. Sundi3D’s fast shipping helps teams refill before shelves are empty.

4. Moving from prototype to production

Designs that work in PLA may not behave the same in molded ABS. Switching to production-like materials earlier and using similar or identical platforms for late-stage prototypes and small batches reduces surprises. Training and strong supplier engagement speed this step.

5. Misaligned expectations

Stakeholders may expect early prints to look and behave like final parts, or they may underestimate the value of rough, quick models. Clear communication about prototype stages—appearance vs. function vs. validation—prevents disappointment.

Across all these challenges, steady materials, guidance, and patient support help teams stay focused on design rather than troubleshooting.

The Future Of Rapid Prototyping: Emerging Trends And Technologies

Looking ahead, 3D printing for rapid prototyping continues to grow more capable and accessible.

Key trends include:

-

Multi-material and full-color printing:

More printers can handle several materials and colors in one build, making realistic, ready-to-show prototypes possible without assembly or painting. -

Smarter design tools:

Artificial intelligence and advanced simulation are entering CAD, offering suggestions for weight savings, strength, and printability, with the promise of data-driven design optimization transforming how engineers approach prototyping. Combined with fast printing, this leads to new design options that would be hard to invent manually. -

New materials:

Fresh polymers, composites, and even metal and ceramic systems are arriving that rival many traditional materials. Hybrid machines that print and machine in the same setup are also becoming more common. -

Sustainability:

There is growing pressure to cut waste and use more bio-based or recyclable materials. PLA and biodegradable PCL already play important roles here.

Sundi3D focuses both on practical performance and responsible material choices, from low-temperature PCL for SUNDIPEN 3D pens to high-quality PLA and industrial-grade ASA. With an in-house R&D and manufacturing base, Sundi3D plans to keep expanding material options and support services as new methods reach the market.

Conclusion

3D printing for rapid prototyping has turned product development from a slow, linear sequence into a fast, looping process where learning happens every day. Instead of waiting weeks for a single machined sample, teams can test several ideas in the same time, compare them directly, and move forward with better data and more confidence.

This shift spans company sizes and industries. Global car makers, small consumer brands, aerospace suppliers, hospitals, schools, and independent makers all use rapid prototyping to stay ahead. The key is not just owning a printer, but matching technologies like FDM, SLA, SLS, PolyJet, or P3 to clear goals and pairing them with suitable materials—from low-cost PLA to industrial engineering plastics and composites.

In a market where speed and learning matter, the ability to try ideas quickly, discard weak ones cheaply, and refine promising designs before cutting tooling has become a basic requirement. That is why material quality and support matter as much as hardware.

Sundi3D brings ten years of focused experience, a wide catalog of standard and industrial filaments, factory-direct pricing, fast 24‑hour shipping from our own production lines, and life-long 24/7 technical support. Whether someone is setting up a first printer in a school lab or expanding a professional prototyping lab inside a factory, the right mix of tools, materials, and expert guidance makes a noticeable difference. With 3D printing for rapid prototyping and a strong partner at your side, the path from idea to reliable product becomes shorter, clearer, and far more productive.

FAQs

What Is The Difference Between Rapid Prototyping And 3D Printing?

3D printing is a manufacturing method that builds objects layer by layer from digital models using materials such as plastics, resins, or powders. Rapid prototyping is an application of these methods that focuses on creating physical models quickly for design and engineering checks.

People sometimes use the terms as if they mean the same thing, but 3D printing also supports tooling and full production, not only early samples. Rapid prototyping refers to the fast, repeated cycle of designing, printing, testing, and refining.

How Much Does Rapid Prototyping With 3D Printing Cost?

Costs for 3D printing for rapid prototyping vary with part size, geometry, and material, but they are usually far lower than machining.

Typical ranges:

-

Simple PLA concept models: about $5–$30 per piece

-

Functional prototypes in engineering plastics: roughly $30–$200 each

Traditional prototypes for similar parts might cost $500–$3,000. For frequent use, in-house printers give the best economics, with materials such as Sundi3D PLA and ASA priced for long-term use, while 3D printing contract manufacturers can support overflow capacity or specialized requirements. Budget planning should also include machine cost, labor, and any finishing work.

What Materials Can Be Used For Rapid Prototyping?

A wide variety of materials support 3D printing for rapid prototyping:

-

FDM: PLA, ABS, PETG, ASA, nylon, TPU, and fiber-filled composites

-

SLA / P3: standard, tough, flexible, and high-temperature resins

-

SLS: mainly nylon powders, sometimes reinforced with carbon fibers

-

PolyJet: rigid, flexible, clear, and full-color photopolymers in many mixes

Sundi3D supplies materials from cost-effective PLA to industrial ASA and also develops custom filaments for special requirements, so teams can match material choice to visual, functional, or durability goals.

How Long Does It Take To Create A Prototype With 3D Printing?

Timeframes for 3D printing for rapid prototyping are short compared to traditional methods:

-

Very small, simple parts: about 2–4 hours

-

Medium-sized or detailed parts: roughly 6–12 hours

-

Large or highly complex parts: 12–24 hours or more

Including CAD work and basic finishing, many teams complete the whole loop from design to a testable part in about one day. Old methods that involved outsourcing often took weeks. With Sundi3D’s fast material delivery, filament supply rarely slows this cycle.

Do I Need Special Training To Use 3D Printing For Prototyping?

Modern hardware and software make 3D printing for rapid prototyping surprisingly accessible. Basic CAD skills and some practice with slicer software are enough to get started, and many people reach a comfortable level within a week or two of regular use.

Online tutorials, community forums, and printer manuals help answer common questions. Teams do not need machining backgrounds; engineers, designers, and students can run most jobs on their own. Sundi3D supports this with 24/7 technical help so new users can solve problems and improve print quality without feeling stuck.

Can 3D Printed Prototypes Be Used For Functional Testing?

Yes. Functional testing is one of the main reasons teams use 3D printing for rapid prototyping. With the right materials—such as ASA, nylon, PETG, or tough resins—printed parts can closely mimic the strength, stiffness, and flexibility of production plastics.

These prototypes handle:

-

Stress and fatigue tests

-

Snap-fit and assembly checks

-

Exposure to heat, vibration, or other environmental factors

They may not always behave exactly like molded parts, but they come close enough to reveal design weaknesses and confirm many performance targets. By using production-like materials from suppliers such as Sundi3D for late-stage prototypes, teams can gather reliable test data before committing to full-scale manufacturing.